The future of fashion may be mostly digital – here’s why

I remember coming across a beautiful poster, folded and inserted inside a National Geographic magazine. It was titled “Hidden Water,” and contained various measurements of how much water it takes to produce different things. The poster said that it requires 2,900 gallons of water to make one pair of blue jeans and estimated the water cost of one cotton t-shirt at 766 gallons. It was my first exposure to “the truth” behind the fashion industry.

The second time came when I watched “The True Cost.” The reason I cannot recommend this documentary enough is that it exposes not only the dark side of fashion, but also points to ills that plague the consumer economy in general. Some companies prefer not to notice issues like dangerous working conditions, unfair pay, and child labor as long as they can keep production costs down. And as it turns out, it happens a lot in the fashion world.

The rise of digital fashion

The term “digital fashion” can mean different things, but it mostly refers to virtual clothing, software-aided fashion product design, and virtual fitting rooms.

Virtual clothing

The Fabricant is a digital fashion house from Denmark. It came into spotlight when it sold the world’s first digital-only garment, the “Iridescence” dress, for $9,500 on blockchain. Richard Ma, CEO of blockchain security firm QuantumStamp, bought it for his wife, Mary Ren.

On their homepage, the company says that they “waste nothing but data and exploit nothing but their imagination.” The Fabricant cooperated with industry leaders like Puma and Tommy Hilfiger on all-digital product design projects, eliminating the need to cut any physical fabric in the process (fabric leftovers add significantly to the ecological footprint of the fashion industry).

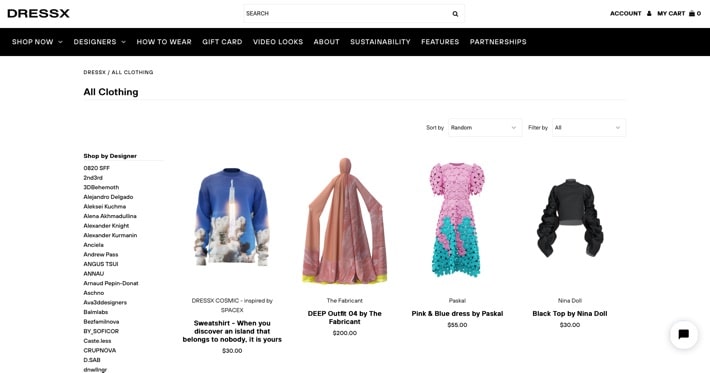

Dress-X is a digital fashion outlet that allows shoppers to purchase virtual clothing items and “wear” them in photos or videos. The way it works is this: you pick an item, upload a photo of you (Dress-X provides recommendations as to what types of photos work best), place an order, and wait 1 to 2 days for the product to arrive in your email inbox.

Dress-X carries virtual collections by roughly 80 designers, including SpaceX- and NASA-inspired pieces, items that feature paintings by Paul Gauguin, Vincent Van Gogh, and Paul Cézanne, and other interesting outfits. Some models are created using a 3D-first approach and tend to look more realistic in photos. Others are designed technically in 2D and the end result depends a lot on the mastery of the professional “dressing” the person in the picture.

Virtual dressing rooms

Technologies that let shoppers try on accessories or footwear have existed for a while. There is Wanna Kicks that lets you try on a pair of sneakers with a smartphone, or Dangle by Face Cake for trying on jewelry. There is also Face® AR by Vertebrae that will superimpose a pair of glasses on your face in 3D, among other things.

While accessories and shoes stay as they are when you try them on, clothes like t-shirts or dresses change shape and deform significantly while worn. So creating virtual try-on systems for clothes is a unique challenge. Still, some companies are up to it.

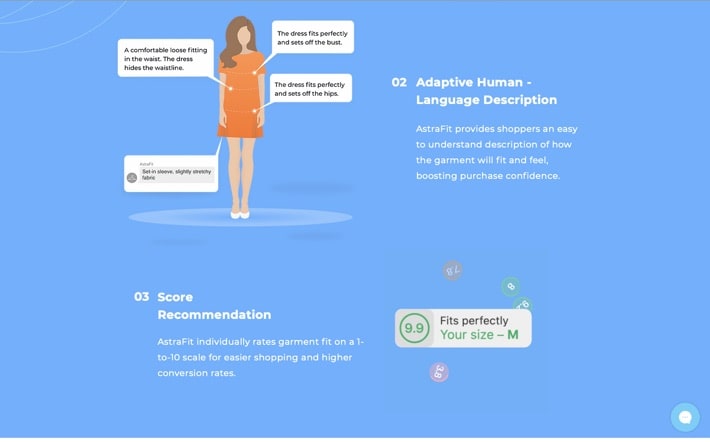

AstraFit is an eCommerce solution that informs shoppers how well a garment fits their particular figure. The way it works is this: store owners digitize all items they want to make available for digital try-on (this is done for all sizes), shoppers enter their sizing when they shop, and a score from 1 to 10 is produced that reflects how well the item fits.

Memory Mirror® by Memomi Lab Inc. is a smart mirror for luxury brands. It allows clients to try on things in-store (using the physical smart mirror) or online. When you use it in-store, the mirror works like a video camera/smart display, allowing you to easily change colors and prints while also getting a 360-degree view of the item. The motto is “try it on without taking off.” The smart mirror will also record your experience and let you share it with family and friends.

triMirror is a Toronto-born technology company that provides virtual fitting solutions for designers, game developers, eCommerce sites, and shoppers. triMirror’s system is based on the virtual avatar the user creates by entering their measurements (you can specify the avatar’s ethnicity, figure type, or even put your face to it). The clothes are then fitted to the shopper’s unique figure, and the software produces a color-coded “tension map” with highlighted tight and loose areas. Users can manipulate garments by pulling them up or down, viewing them from various angles, etc.

Virtual measurements

Japanese entrepreneur Yusaku Maezawa is known in the West mostly for his dearMoon project. In his home country, he’s the man behind Zozotown, one of Japan’s largest online fashion retailers. In 2018, it launched ZOZOSUIT – a skintight body measurement suit that allowed users to upload their parameters to the site and order custom-tailored clothes.

Despite having excited a lot of shoppers, the novelty failed to drive sales, reportedly due to the lack of accuracy. In fall 2020, ZOZO Inc. unveiled ZOZOSUIT 2, an improved version of the body-scanning suit. It has 50 times more fiducial markers, and is thus much more accurate.

ZOZO Inc. says it’s open to cooperation with companies that need body-scanning technology, be it in the fashion industry or not. Moreover, the assortment of ZOZO measurement technologies now also includes ZOZOMAT, a foot scanning mat, and ZOZOGLASS, a pair of goggles that help you pick the best foundation for your skin tone.

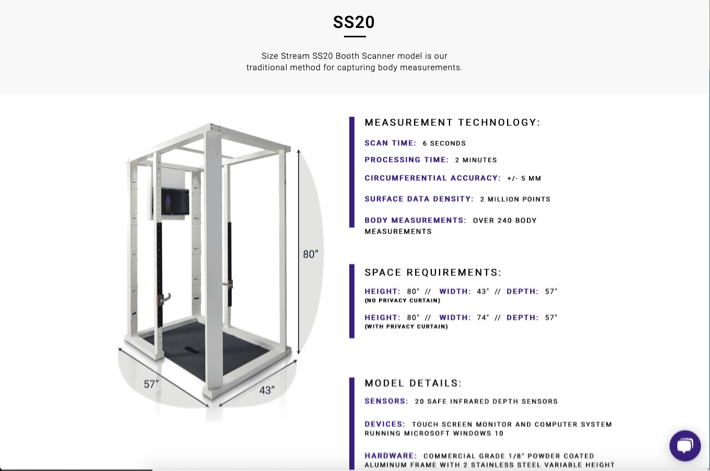

Size Stream is another company offering a 3D body measuring platform, this time from their headquarters in North Carolina, USA. The company has two body-scanning solutions: an SS20 Booth Scanner and a mobile app that lets users take measurements at home.

Solutions that facilitate body measuring can reduce return rates, decrease waste, help with buying virtual outfits, and propel custom-made clothes into the mainstream, especially if combined with 3D printing technologies.

Virtual R&D

These days, many brands turn to digital technologies to create prototypes of future garments.

Anna Franziska Michel is the founder of YOONA, an AI-based tool that helps brands design clothes. On one hand, it’s targeted at those who create for the mainstream. On the other hand, it helps you come up with highly-personalized designs. Michel said in an interview:

More than 70% of the collections that bring the biggest revenue are created according to historical data, performance analysis, or through copying/modification of bestsellers of the brand itself or its competitors. These processes cannot be seen as creative and thus should be automated.

With YOONA, you can feed performance analytics, technical drawings, moodboards, and other data into the system and get tons of designs with the push of a button. Once they have been generated, you can simply save ones you like. YOONA also helps brands create highly-personalized clothing based on customer feedback. According to Anna Franziska Michel, such models are appreciated more and worn longer.

In Conclusion

With the rise of AI (such as deep learning and other technologies), it became possible to incorporate digital technologies in fashion design. Modern tech helps provide more engaging shopping experiences, minimize return rates, decrease waste, or even substitute physical garments with virtual outfits in some cases.

If the tendency continues, the fashion industry will be more and more reliant on technology in the future, and everyone doing it the old way (which has been proven to be unsustainable) will have to adapt.

Related Blogs

Re-imagining the shopping experience with Computer Vision and AI

Read Article